|

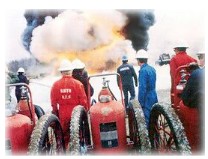

Over the past 40 years, the demand for transportation,

storage, and handling of flammable fuels that fall under the

fire protection classification of "High Hazard"

has increased drastically. This has often occurred at a

faster rate than most fire protection requirements or

coverages. Recent trends toward automation and work force

reductions have placed additional demands upon fast response

types of fire fighting equipment. With fewer people

available to respond to emergency situations where higher

fire loads exist, portable wheeled fire extinguishers that

provide a quicker, more effective extinguishment solution

than water, should be utilized.

|

Portable

wheeled fire extinguishers have been around for well

over 50 years and were, in those early years,

referred to as "Wheeled Engines". The

first true market niche for this equipment was

established during the early 1940s when it was used

to protect military airport ramps.

Wheeled

extinguishers can be easily operated by one person

and are considered to be portable extinguishers

falling under The National Fire Protection

Association's Standard NFPA-10. |

|

The

portable "wheeled" units are differentiated from

"hand portable" types often simply on the basis of

their capacity or total weight. For example, the portable

extinguisher design standard for dry chemical extinguishers

ANSI/UL-299 specifies that hand portable models not have a

total charged gross weight exceeding 60 pounds.

Wheeled units are available in a variety of model sizes that

feature extinguishing agents such as carbon dioxide, dry

chemical, halons, dry powder, and AFFF-type foam pre-mix

solutions. Agent capacities of 30 to 350 pounds are offered,

with many of the smaller-sized units sometimes being

glorified hand portables on wheels marketed to meet minimum

high hazard requirements or for added ease of mobility.

Basic

Extinguisher Operation Principles - NAFED

The

primary fire protection value of wheeled fire extinguishers

is in their ability to:

-

Contain

greater extinguishing agent capacities

-

Deliver

higher agent flow rates

-

Provide

additional fire fighting ranges

-

Extend

discharge times.

These

unique fire fighting characteristics are also extremely

valuable during emergency situations in providing assistance

to various rescue and evacuation efforts.

Basic

Extinguisher Operation Principles

|

|

There

are basically four operation principles in which wheeled

extinguishers are designed and manufactured.

Self-Expelling:

These models typically contain the extinguishing agent

within a single high-pressure cylinder. When the cylinder

valve is opened, the extinguishing agent's own vapor

pressure forces the agent to travel up a pick-up tube,

through the operating valve and out the discharge hose

nozzle valve onto the fire. This principle is primarily

limited to carbon dioxide wheeled models which are not

equipped with pressure gauges to indicate charge status. |

|

(Buckeye)

50 lb.

Carbon Dioxide

"Self Expelling" Mode |

Stored

Pressure: With this principle, the extinguishing agent

and expellant gas source (normally super pressurized

nitrogen) is contained within the same cylinder. Upon

actuation of an operating valve, internal pressure forces

the extinguishing agent up the pick-up tube, through the

operation valve and out the discharge hose nozzle valve on

to the fire. This configuration of hardware is normally the

least expensive.

Pressure Transfer: This concept consists of separate

extinguishing agent and expellant gas cylinders. The

expellant (normally compressed nitrogen) is contained within

a specifically engineered volume and sized high-pressure

cylinder designed to properly pressurize and discharge the

total contents of the agent cylinder. Upon opening of the

expellant gas cylinder operating valve, expellant gas is

transferred through a special gas distribution tube assembly

that fluidizes and pressurizes the agent cylinder to a

pre-determined head pressure. This pressure permits the

extinguishing agent to travel up the agent tank pick-up tube

and out the discharge nozzle valve on to the fire. This

concept is less susceptible to vibration pressure losses in

rugged and abusive environments. The separate unpressurized

agent cylinder allows simple agent examination and quick

recharges in the field.

Regulated Supply and Demand: While similar to the

pressure transfer principle in most ways, this concept

utilizes a much larger volume expellant gas cylinder source

and a pressure regulator. As the extinguishing agent is

discharged, the regulator will flow and meter additional

expellant gas pressure to the agent tank, providing a more

consistent operating pressure. This ensures stable agent

flow rates and ranges throughout the fire fighting evolution.

While usually higher priced, many fire hazards justify the

additional cost associated with the regulator and larger gas

cylinder necessary on these models.

Extinguisher

Options

There

are a large variety of options available to wheeled

extinguishers, with the nozzle design and wheel

configuration being two of the most often misunderstood and

incorrectly applied.

Wheel diameters of 16 to 44 inches are commonly offered in

various widths and finished rolling surface bases. The large

diameter wheel types will provide superior mobility and ease

of operation over uneven surfaces like potholes,

|

|

sidewalks

or small steps. Wide 6-inch wheel bases provide additional

versatility on soft surfaces such as loose sand, gravel or

sod. When spark reduction or the marking of floor finishes

is a consideration, the pneumatic, semi-pneumatic and

rubber-banded wheels should be utilized rather than the

steel base types. Because pneumatic wheels will absorb some

surface shock, they generally deliver the best unit ride and

are often selected for large airport ramp areas where towing

operations exist. The semi-pneumatic and rubber-banded

wheels eliminate potential flat problems in and around areas

where sharp objects may be present.

Before purchasing any unit, always check to ensure the

overall width of the unit, under its specific wheel option

configuration, will fit through any necessary aisles or door

passageways.

The nozzle design of the wheeled extinguisher directly

contributes to various operation characteristics such as the

discharge range, pattern, velocity, flow rate and fire

rating.

Range information published by manufacturers can often be

somewhat misleading. The focus here should be on the unit's

"effective range" established through actual

fire-fighting evolutions, subject to thermal up- draft

factors. Different internal nozzle bore designs provide

various agent stream patterns, flow rates and velocities.

Discharge characteristics should be properly matched to the

particular fire hazard. For example, the venturi designs

generally provide higher velocities and ranges at lower

agent flow rates, which work well on large class

"A" fire applications. On the other hand,

cone-type nozzle designs normally reduce agent velocity for

a softer discharge, making them ideal around fuel-in-depth

situations where splashing of fuels in, and around, confined

areas could present problems to firefighters.

Equipment specifiers should also keep in mind that the

portable extinguisher class "B" rating system is

based on minimum discharge times and only one type of fire

configuration. For the manufacturers to obtain higher and

more impressive ratings, they must increase discharge times

by cutting back agent flow rates, which is detrimental to

the extinguishment of many other common industry class

"B" fire configurations. Agent flow rates become

critical in obstacle, gravity, 3-dimensional and pressure

fire configurations. The NFPA 10 standard recognizes this

and specifically states under several such hazard areas that

"The system used to rate extinguishers on class

"B" fires is not directly applicable to these

types of hazards." For most wheel unit applications,

higher attention to the agent flow rates over extinguisher

ratings is in order. Most manufacturers can provide

recommendations and furnish support data.

Maintenance

Wheeled

fire extinguishers, like hand portable models, are

mechanical devices that require periodic service for optimum

performance and reliability. Both OSHA and NFPA requirements

specify maximum extinguisher inspection intervals of 30 days

and for maintenance to be performed at least annually.

Training

When

properly selected and maintained, wheeled fire extinguishers

provide an exceptional fire fighting resource for the high

risk industries of today. For companies to benefit and reap

the full potential of these extremely effective units,

training programs properly designed to demonstrate and

familiarize operators with their impressive capabilities

should also be regularly conducted.

|